Although sometimes ignored, packaging design and manufacturing are important parts of a company’s supply chain. Most companies get their packaging from another manufacturer, since it is more efficient than making it at the plant. Do you want to know how packaging works in the U.S.? Keep reading.

Packaging Specialists

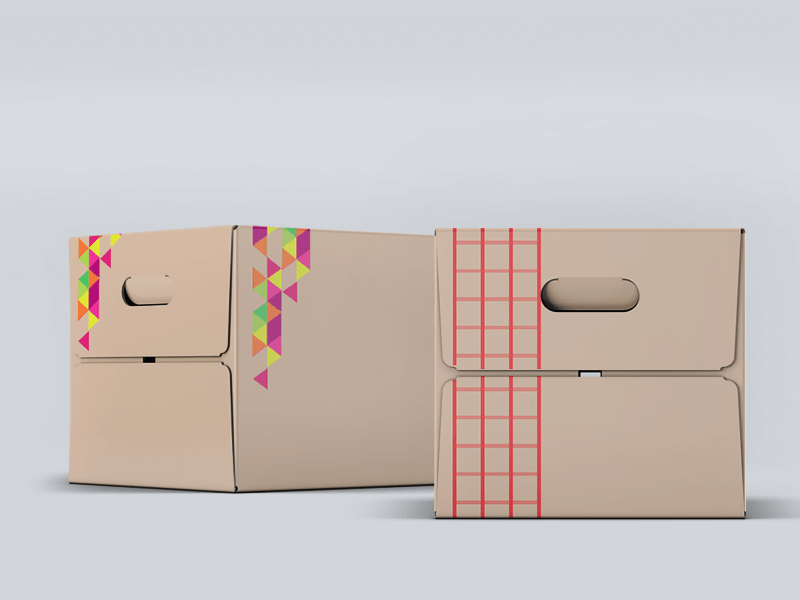

As we said before, there are companies dedicated to design, manufacture and distribute packaging for other brands. At VMA LOGDIST that’s what we do. We provide a complete and specialized service that encompasses design, testing, printing, manufacturing and delivering. We have worked with all sorts of companies, creating many different designs for all kinds of products.

To do our job, we manage two stages of the process: design and manufacturing. That’s right, we make our packaging from scratch and add the requirements that you ask for. Here we will tell you more about our process.

DESIGN

Designing the packaging is the first part of the process. It’s where your ideas and our packaging experience combine to create something meaningful and unique for you and your customers.

- Structure: The shape of any packaging is never random. We take in mind the characteristics of your product and then start designing.

- Materials: We manage a wide variety of materials, such as standard cardboard, corrugated, plastic, paper, wood, foam and others.

- Testing: Before the manufacturing stage, we always test the efficiency, durability, and general outcome of a packaging. If everything is in place, then we start manufacturing.

MANUFACTURING

The second part of the process is getting on with the packaging production. This is where the design stage takes form and becomes a tangible reality that you can see, touch and assemble.

- Printing: When a box requires a custom design, we need a printing plate to create it. The plate is created during the design stage, but once it’s made, the corrugated sheet gets printed by it. Now it has color, your logo, perhaps a slogan or message and other details.

- Cutting: Finally, the sheet is cut with the help of a cutting die specifically designed for your brand, and the packaging is done. Now it only needs to be assembled with your product inside and there you go. Your package is ready.Now that you know how packaging design and manufacturing works, you are ready to get the best service in the U.S. Contact us to get to know more. Let’s wrap up that project of yours!